8 Simple Techniques For Sheroz Earthworks

8 Simple Techniques For Sheroz Earthworks

Blog Article

Sheroz Earthworks for Beginners

Table of ContentsSheroz Earthworks - QuestionsSome Known Questions About Sheroz Earthworks.Sheroz Earthworks Fundamentals ExplainedThe smart Trick of Sheroz Earthworks That Nobody is DiscussingA Biased View of Sheroz EarthworksExamine This Report on Sheroz Earthworks

Today, Smart Construction Remote connects over 700 equipments on jobsites to offices, conserving hundreds of hours formerly invested by jobsite supervisors, land surveyors and designers commuting from offices to jobsites. So to summarise, the first one decade of Komatsu's intelligent device control have actually been noted by a decade of one-of-a-kind innovation, continual learning and growth with customers.

Right here's to the following ten years! Web content created in organization with Komatsu.

In the rapidly advancing globe of construction, accuracy and efficiency are vital. 3D device control, a system that uses general practitioner and various other sensors to guide equipment with determine accuracy, is revolutionising the sector - https://www.magcloud.com/user/sherozau. From its early days of 2D advice, this technology has progressed significantly, making jobs that when called for hands-on treatment currently possible with marginal human input

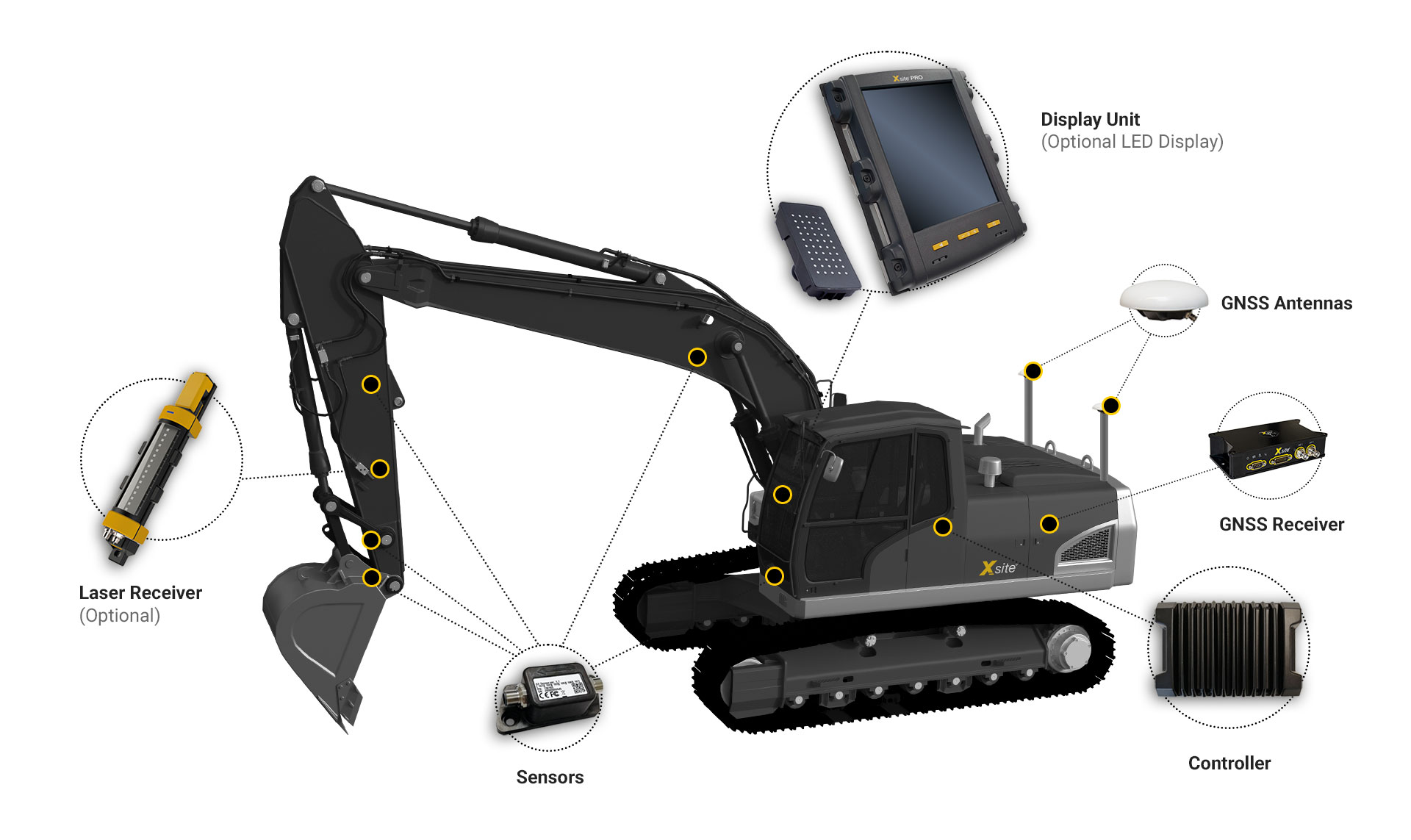

At the core of any 3D maker control system are GNSS receivers and antennas, recording satellite signals to identify the maker's specific area. Onboard computer systems and control boxes procedure this information and communicate with the machinery.

Sheroz Earthworks for Beginners

This includes setting up GNSS receivers, calibrating sensing units, and configuring the machine control software - topcon. The magic of 3D machine control lies in its real-time information collection and processing.

Interface give real-time updates on the device's setting and required adjustments, making sure exact control. Numerous elements impact precision, consisting of satellite signal top quality and sensor calibration. Strategies like Real-Time Kinematic (RTK) placing and Specific Point Positioning (PPP) improve precision, making certain the highest precision. In building, 3D device control is utilized for earthmoving, grading, paving, and excavation, ensuring tasks are finished to precise requirements.

The smart Trick of Sheroz Earthworks That Nobody is Discussing

3D maker control considerably enhances effectiveness by minimizing rework and minimising product wastage, leading to much faster and a lot more economical job conclusion. The modern technology makes sure every task is performed exactly as prepared, causing regularly high-quality job. One of one of the most compelling benefits of 3D maker control is the considerable cost savings it offers.

Gas consumption is optimized because makers run straight from the source a lot more effectively and avoid unnecessary activities. By lowering human mistake and restricting direct exposure to unsafe environments, 3D equipment control enhances employee security and reduces accidents.

From building to mining, this innovation makes certain tasks are carried out properly and safely, reducing costs and improving outcomes. As innovations continue, the capacity for 3D maker control to additionally enhance productivity and safety and security expands. Welcoming this technology is important for sector experts wanting to stay competitive and achieve the highest standards in their projects.

What Does Sheroz Earthworks Mean?

Discover the future of accuracy and efficiency now! Also, have a look at our most recent YouTube video clip on the FJD H36 Motor Control System to see the innovation at work: See now.

For many years, we've seen operators with lots of experience do some outstanding things with their equipments. Maybe they have an eye for adjustments that boost accuracy, or maybe they understand which attributes of their device to use and when to improve performance or performance - https://www.artstation.com/floydoverbeck1/profile. However with today's advancements in heavy tools technology, also proficient drivers can gain from a real-time aid to boost their everyday performance (trimble repair parts).

This is where equipment control systems consider. A system with an in-cab tablet that integrates sensors and general practitioners technology can support accuracy and effectiveness. Volvo Building EquipmentLet's check out excavators as our first instance. Some excavators come with machine control systems that lead the driver with functions to automate the excavating process.

The Best Guide To Sheroz Earthworks

With this added accuracy, rework is virtually gotten rid of, allowing the driver to complete the project in a timely manner and relocate to the next task. For those functioning on dangerous or difficult jobsites, remote-controlled services open new chances. This excellent add-on allows you to run an excavator from a distance in locations with hazardous materials (like in a potash mine) or inadequate ground conditions (like mud).

Maker control systems supply beneficial benefits to even more than simply excavator operators. If you have a truck come in with a target of 23 bunches, your operator can load their pail and dynamically evaluate itoften without also being fixed.

This implies the driver can see the precise weight of the lots they're about to dump (fj dynamics auto steer price). On-board considering supplies real-time insight into the bucket's lots to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building EquipmentIf they dump 12 lots on the very first pass, the following pail requires to weigh 11 heaps

The Ultimate Guide To Sheroz Earthworks

The majority of procedures utilize an on-board weighing app to make certain that the load is exact prior to they send their trucks to the ranges, which is necessary because the range weight is what's used for invoicing and invoicing functions. A number of manufacturers include some kind of considering program on their loaders. Some also have features that allow business to monitor and control the complete lots of multiple vehicles.

Report this page